Paper pulp packaging is now a Main emphasis for firms globally as they shift from unsustainable resources towards eco-helpful options. Molded pulp packaging offers a sustainable and price-helpful way to provide significant-high quality packaging that's customizable and biodegradable. one particular area driving innovation will be the introduction of substantial-effectiveness pulp molding equipment, just like the Dwellpac Semi-Hotpress Machine. These equipment support organizations streamline output whilst guaranteeing precision and trustworthiness.This article will explore The real key capabilities of high-performance pulp molding machines, maintenance guidelines for long-term use, tactics to chop costs although maximizing output, And the way automation improves creation and excellent. regardless of whether you are a company operator or a packaging Skilled, you are going to acquire valuable insights that can help optimize your output course of action.

Table of contents:

important options of High-effectiveness Pulp Molding devices

upkeep tricks for lengthy-time period equipment efficiency

Expense-conserving Strategies in Production

How Automation enhances Output and top quality

vital Features of large-Efficiency Pulp Molding devices

higher-performance pulp molding devices are revolutionizing how molded pulp makers work. The Dwellpac Semi-Hotpress Machine is one particular these types of example. It stands out for its Sophisticated control technique, significant clamping precision, and seamless hydraulic efficiency. With characteristics like precision shaping and eco-friendly mold urgent technologies, it makes certain that each and every eco-welcoming box packaging product or service is dependable in top quality and durability. This is significant for industries needing personalized options like food packaging, electronics, and industrial components. these types of machines also support A variety of personalized molded pulp packaging needs, featuring considerable versatility in output.

servicing techniques for prolonged-time period equipment effectiveness

retaining a pulp molding machine is significant to making sure consistent output and maximizing its lifespan. common upkeep tasks incorporate cleaning the molding surfaces, inspecting hydraulic units for use and tear, and ensuring the Manage method is updated for peak efficiency. The Dwellpac device is intended to simplify these processes, allowing for molded pulp makers to streamline repairs. Regular inspections and proactive care not just reduce sudden breakdowns but in addition help manage the precision criteria necessary for high-top quality paper pulp packaging.

Value-preserving Strategies in generation

Cost-performance is a primary worry for molded pulp producers. to save lots of fees while protecting top quality, they can enhance substance use by leveraging successful pulp mold pressing engineering to attenuate waste, put money into Electricity-successful machinery much like the Dwellpac Semi-Hotpress equipment to lessen Strength intake, and educate team to completely benefit from State-of-the-art devices to stop faults that lead to inconsistencies or wastage. On top of that, ordering eco-helpful supplies in bulk can assist benefit from decrease prices and lessen General generation expenditures. By adopting these strategies, brands can stay aggressive while providing large-top quality, personalized eco-welcoming packaging to clientele.

How Automation enhances Output and high-quality

Automation has grown to be a pivotal facet of contemporary production procedures. Highly developed pulp molding machine brands, which include Dwellpac, combine automation to enhance operational performance. Automated methods, by like functions like intuitive Management panels and actual-time precision monitoring, reduce the chance of human mistakes. This makes sure that every single mould made fulfills strict high quality standards. With automation, enterprises also can deal with substantial-scale manufacturing operates extra effectively, meeting precise deadlines although making molded fiber packaging at competitive rates. In addition, the reliable high quality attained by automation reinforces customer belief in eco-helpful packaging answers.

higher-effectiveness pulp molding machines are enabling firms to satisfy raising website demand from customers for sustainable packaging solutions. By purchasing Superior technologies, corporations can generate tailored molded paper pulp items that not just defend the atmosphere but will also deliver remarkable functionality and durability. With innovative machines and considerate maintenance tactics, companies can prevail over generation challenges, minimize operational prices, and give eco-pleasant items that cater to worldwide sustainability targets.

Haley Joel Osment Then & Now!

Haley Joel Osment Then & Now! Sam Woods Then & Now!

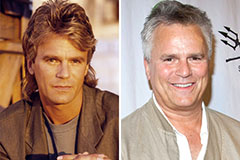

Sam Woods Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now! Peter Billingsley Then & Now!

Peter Billingsley Then & Now! Nicholle Tom Then & Now!

Nicholle Tom Then & Now!